.png)

.png)

.png)

.png)

.png)

.png)

.png)

Magnets are fascinating objects, with unique properties that have been utilized in various fields for centuries. But have you ever wondered, what happens when you cut a magnet in half? Does it lose its magnetism? Does the magnet break into two weaker magnets, or does something else happen? In this guide, we’ll explore the science behind magnet cutting, how it affects the magnet’s properties, and what you can expect after you cut a magnet.

A magnet is any material that produces a magnetic field. This field attracts or repels other materials that are magnetic. The fundamental characteristic of a magnet is its ability to attract or repel certain metals, like iron, nickel, and cobalt. Magnets can exist in various forms, from small refrigerator magnets to massive industrial magnets used in electric motors.

Magnets have two opposite poles—North and South—where the magnetic force is strongest. Magnetic fields flow from the North pole and curve around to the South pole. These fields are invisible but can affect other magnetic materials within their range. The strength of a magnet is determined by how many magnetic domains (tiny magnetic fields within the material) are aligned in the same direction.

Every magnet has two poles, North and South, and opposite poles attract while similar poles repel each other. Cutting a magnet does not eliminate these poles; instead, it creates new poles at the cut edges.

Magnetic field lines are imaginary lines that represent the direction and strength of a magnetic field. They emerge from the North pole and curve around to the South pole. The closer the lines are to each other, the stronger the magnetic field in that area.

Magnetic domains are regions within a magnet where the magnetic moments of atoms are aligned in the same direction. When a magnet is cut, the domains realign to create new North and South poles at the newly cut surfaces.

When you cut a magnet, you don’t destroy its magnetic properties. Instead, each half of the magnet retains its magnetism, and new magnetic poles are created at the newly cut faces. For example, if you cut a bar magnet in half, each piece will have a North pole and a South pole, forming two smaller magnets.

|

Effect |

Description |

|---|---|

|

Magnetic Poles Form |

Each piece will form its own North and South poles. |

|

Magnetic Strength |

Each piece may be slightly weaker than the original, but it still retains its magnetism. |

|

Magnetic Field Changes |

The shape and strength of the magnetic field around each piece may change. |

|

Physical Changes |

The magnet’s shape and size are altered, but its basic magnetic properties remain intact. |

When you cut a magnet, the internal magnetic domains rearrange themselves. The magnetic domains are responsible for the magnet’s overall magnetic behavior. After the cut, the domains at the newly exposed surfaces realign, forming new poles. Below is a list of why this occurs:

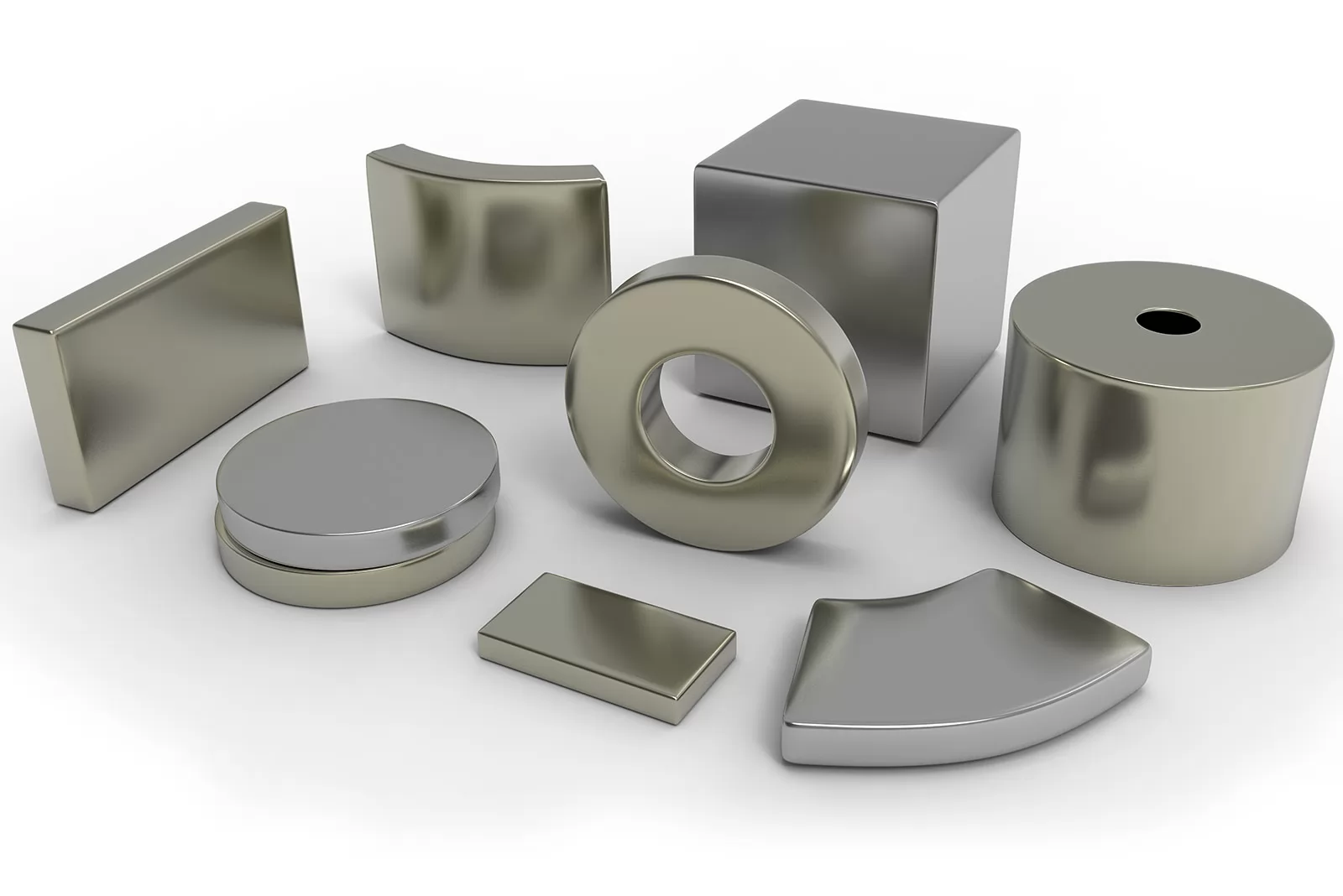

Different types of magnets may respond differently when cut. Here’s a list showing how various magnet types react to being cut:

|

Type of Magnet |

Reaction to Cutting |

Additional Notes |

|---|---|---|

|

Permanent Magnets |

Remain magnetic with new poles at the cut surfaces. |

Examples: Neodymium, Ferrite magnets. |

|

Electromagnets |

Do not remain magnetic unless re-energized with electricity. |

Cutting disconnects the electrical circuit. |

|

Rare Earth Magnets |

Retain magnetism but may be more fragile and require extra care. |

Commonly used in strong applications like motors. |

|

Flexible Magnets |

Maintain magnetism but may lose some strength. |

Often used in flexible applications like fridge magnets. |

While cutting magnets may seem simple, there are a few practical considerations to keep in mind. Here are the key points to remember:

|

Cutting Scenario |

Magnet Strength After Cutting |

|---|---|

|

Large, Thick Magnet |

The strength of each piece may be weaker, but still magnetic. |

|

Small Magnet |

Cutting into smaller pieces can reduce the overall strength, but the pieces remain magnetic. |

|

Rare Earth Magnets |

These magnets may lose a significant portion of their strength, especially if cut improperly. |

Cutting magnets can result in a loss of magnetic strength, especially if the pieces are small. However, the magnet will still retain its fundamental properties.

Sharp edges and small fragments can be a hazard when cutting magnets. Always use proper cutting equipment and take necessary safety measures.

To cut magnets accurately and safely, specialized tools such as diamond-tipped saws or laser cutters are recommended. These tools help preserve the magnet’s properties while ensuring precision.

Choosing the right neodymium magnet is essential to ensure optimal performance for your application. Here are key factors to consider when selecting the ideal magnet:

Application Requirements: Determine the necessary strength, size, and shape.

Operating Environment: Consider temperature and humidity levels.

Coating Options: Choose protective finishes for durability.

Tongchuang Magnetic, a leading neodymium magnet manufacturer, offers a wide range of high-performance magnets with customizable options. Their expertise, state-of-the-art production facilities, and commitment to innovation make them a top choice for industries worldwide.

By carefully evaluating these factors, you can select a neodymium magnet that perfectly matches your needs, maximizing efficiency and performance in your application.

Cutting a magnet doesn’t destroy its magnetism. Instead, each cut piece forms new North and South poles, maintaining the magnet’s magnetic properties. While cutting magnets can weaken their strength slightly, they remain functional and magnetic. Understanding this principle is key in various applications where magnets need to be shaped or sized.

Interested in learning more about magnets or need high-quality magnet solutions for your projects? Contact our team of experts to explore a wide range of magnet types and get the best solutions for your needs.