.png)

.png)

.png)

.png)

.png)

.png)

.png)

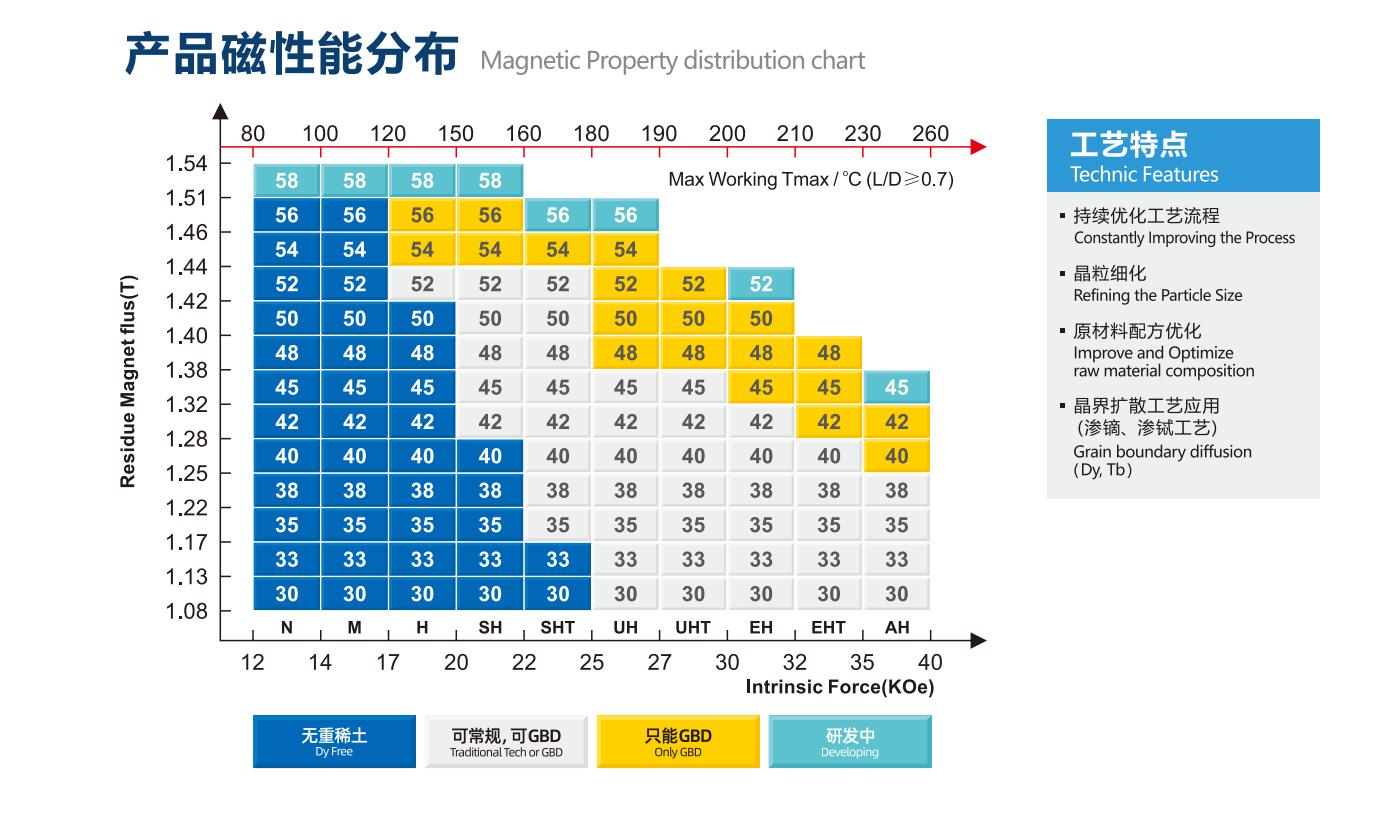

Since its establishment, Tongchuang has always focused on technological research and innovation, and has a high-level R&D team that has been deeply involved in the neodymium iron boron industry for nearly 30 years. Led by the market and customer demand, backed by NIMTE (Chinese Academy of Sciences) and Postdoctoral Workstation, and with professional engineering and technical personnel as the outposts, we can provide customers with forward-looking consulting and advice on the permanent magnet industry, assist customers in improving magnetic circuit design, solving problems encountered during the use of magnets, and provide the best cost-effective permanent magnet products to maximize the efficiency of magnets.

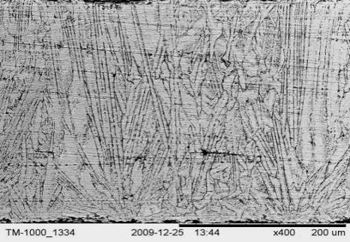

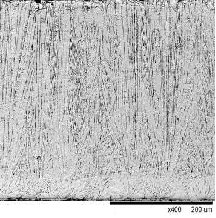

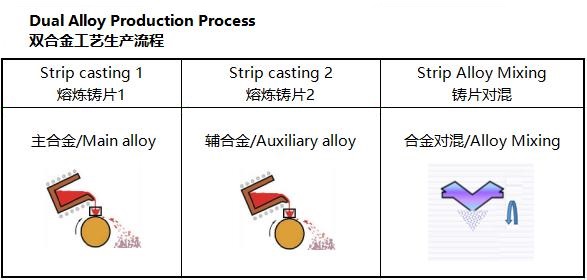

Cerium containing neodymium iron boron magnets refer to the addition of high abundance rare earth elements (lanthanum La, cerium Ce) to the formula of neodymium iron boron NdFeB magnets, reducing the amount of praseodymium neodymium and achieving the goal of cost reduction.

Molecular formula:Nd2Fe14B(Ce2Fe14B,RE2Fe14B)

In recent years, the company has developed a series of high abundance rare earth magnet brand products. In terms of application, it has broken through the limitations of high abundance rare earth magnets concentrated in low-end fields such as maqnetic adsorption, maanetic separation, E-scooter, luggage buckles, door buckles, toys, etc., and expanded them to more stringent application fields such as acoustic devices and industrial motors.

Typical application: E-scooter motor

1. Large quantity, requiring ultimate cost-effectiveness;

2. High requirements for rounding;

3. High requirements for magnetic flux range control;

Permanent magnets, also known as permanent magnets, can be natural products or artificially manufactured (the strongest magnets are neodymium iron boron magnets). A material with a wide hysteresis loop, high coercivity Hcj, and high remanence Br that can maintain constant magnetism once magnetized. In applications, permanent magnets work in the demagnetization part of the second quadrant of the magnetic hysteresis loop after deep magnetic saturation and magnetization. Permanent magnets should have the highest possible coercivity Hc, remanence Br, and maximum magnetic energy product (BH) max to ensure maximum storage of magnetic energy and stable magnetism.

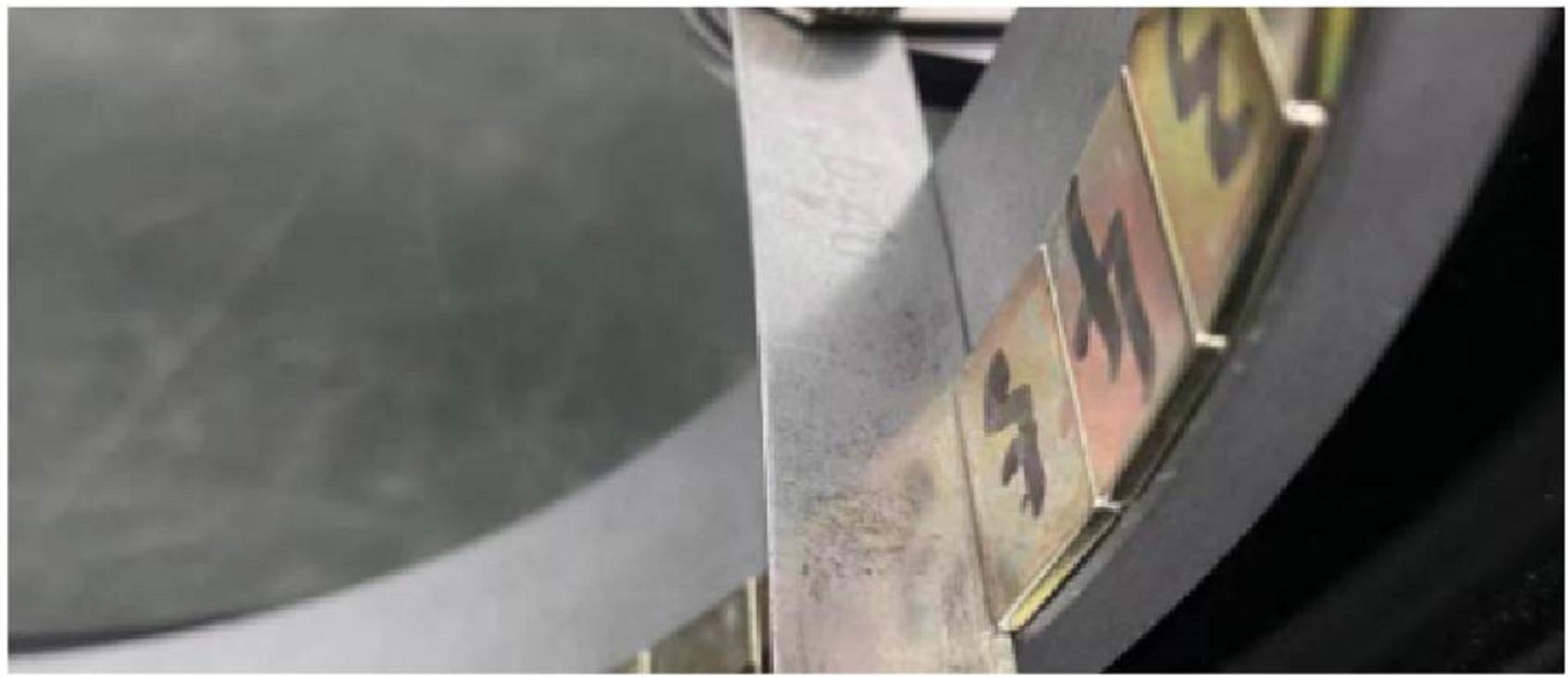

With rich manufacturing experience and advanced equipment, Tongchuang provides complete engineering support for the design, modelling, prototyping and optimization of magnetic products, continuously improving the functionality of magnetic materials and integrating them into the products which provided to customers.

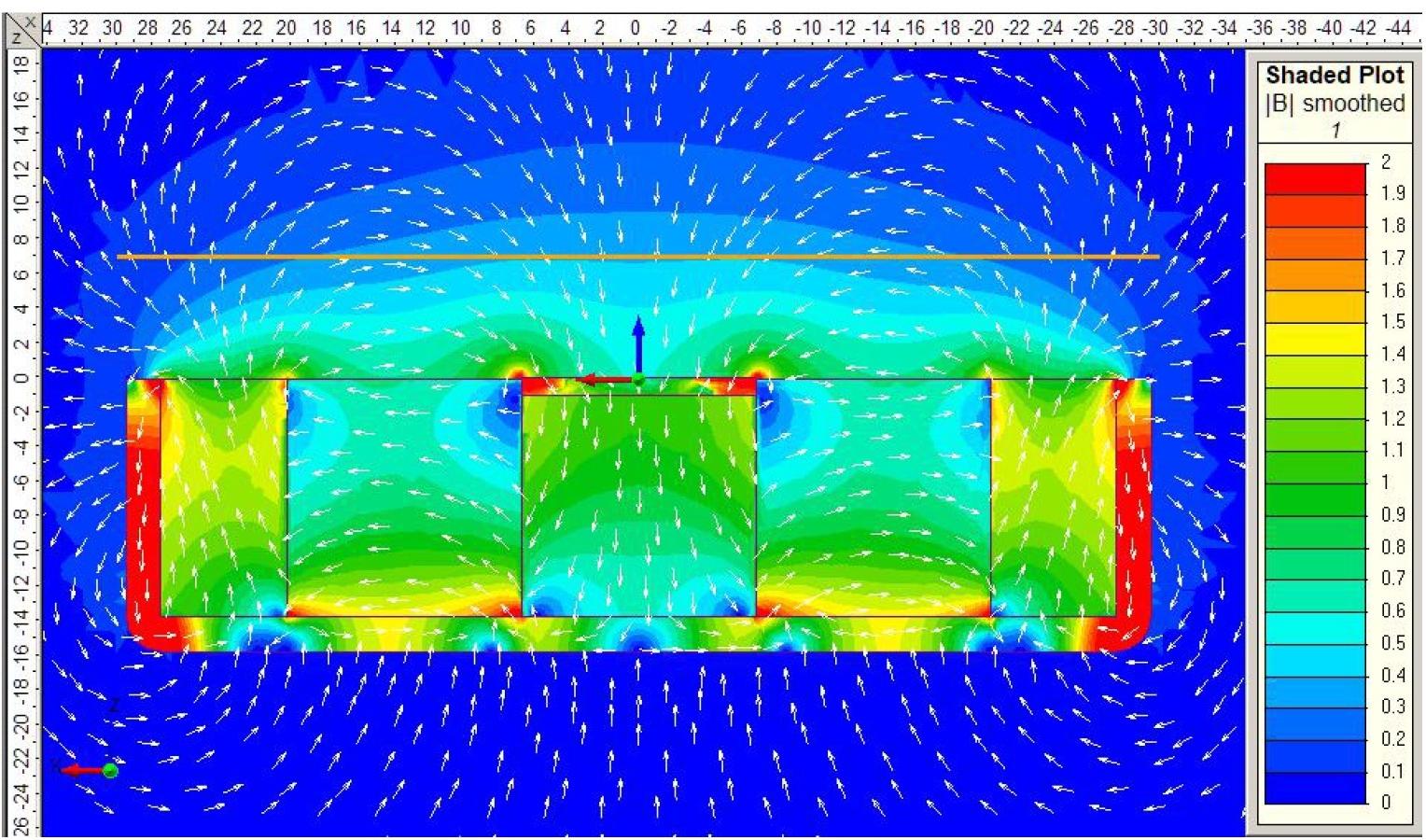

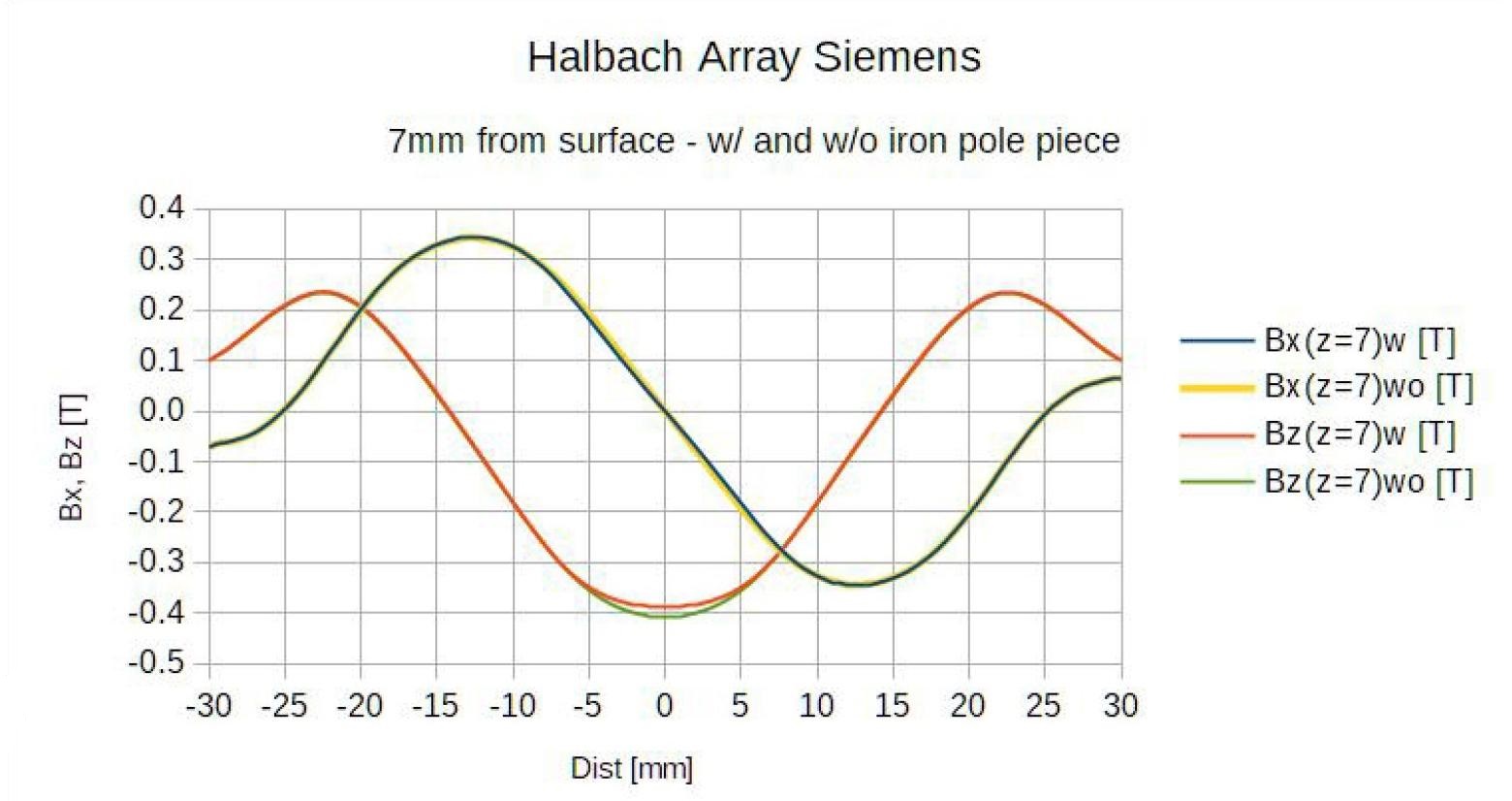

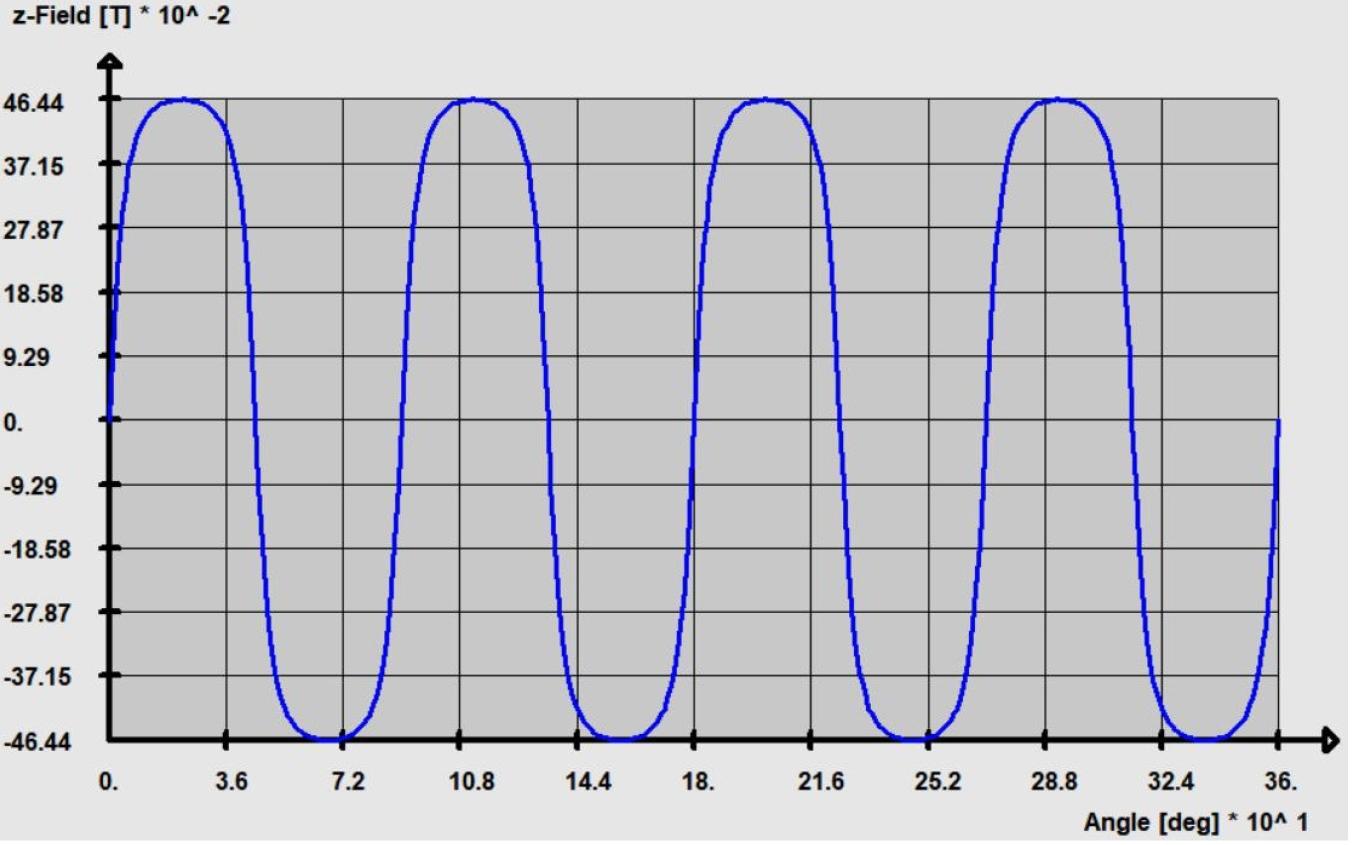

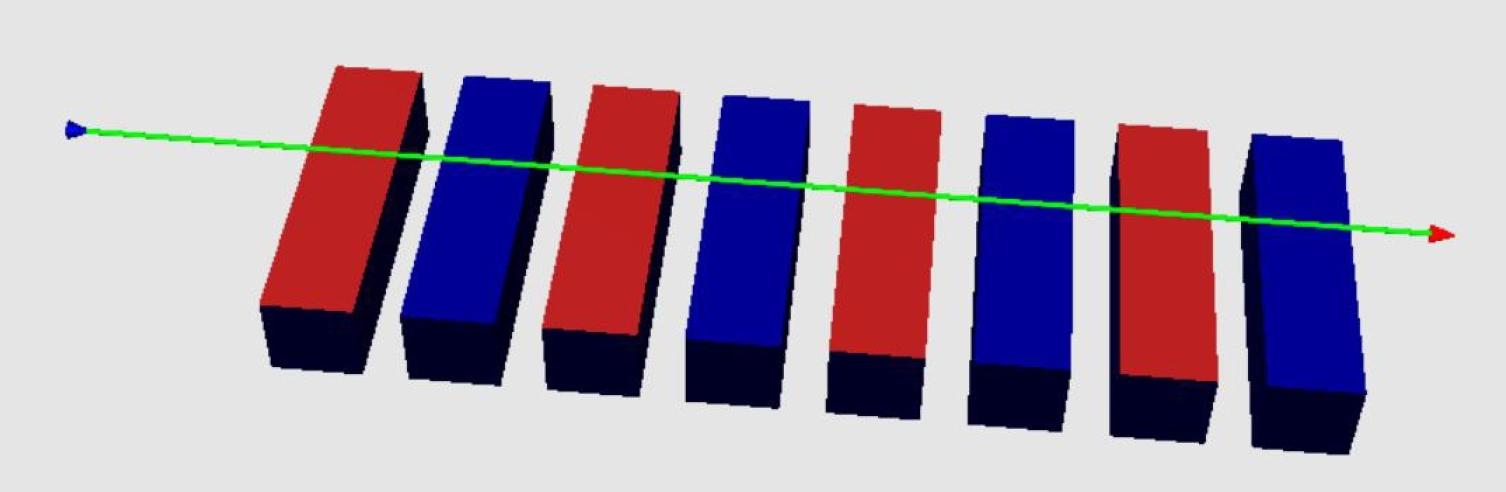

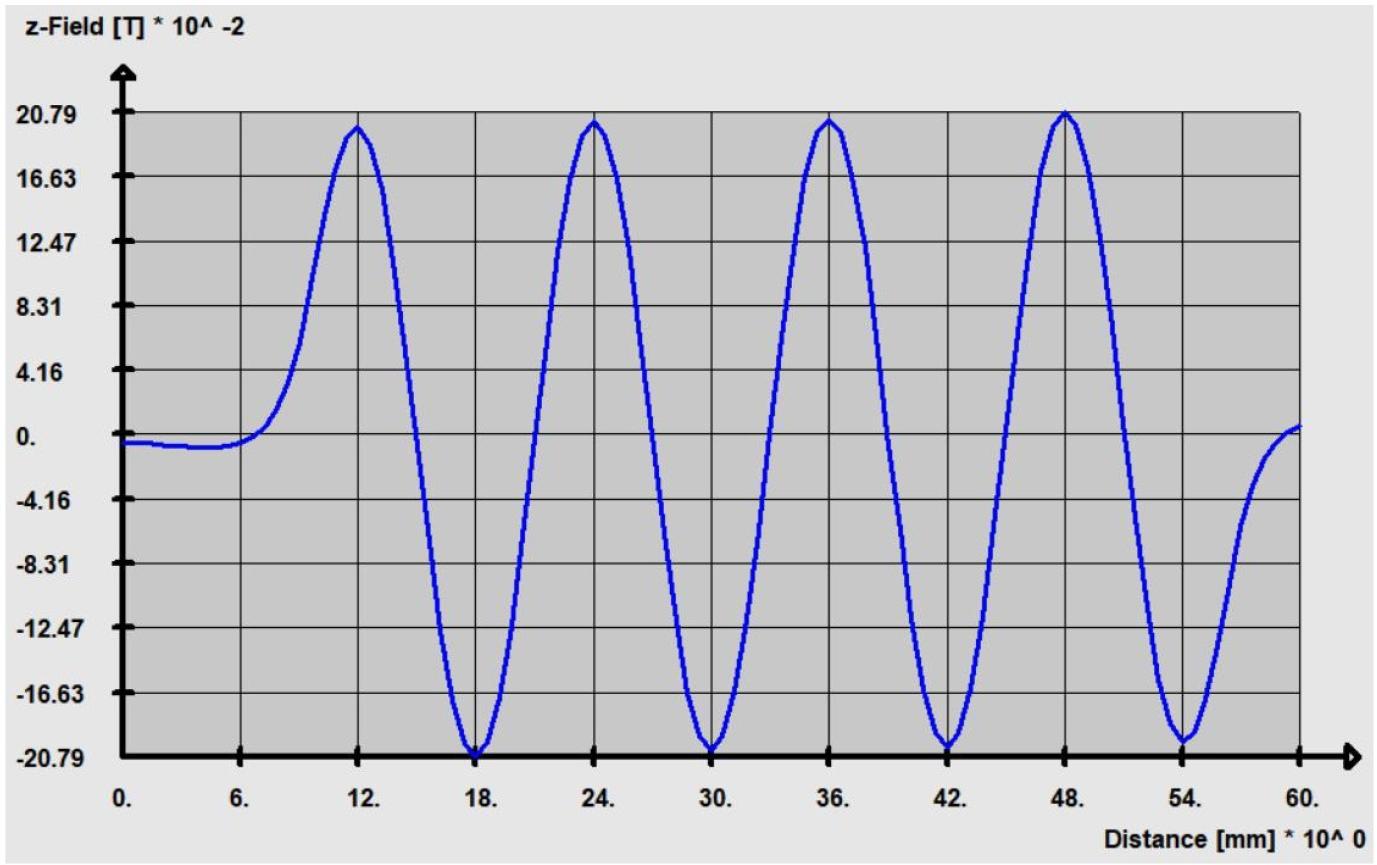

TC has 2D and 3D Finite Element Analysis (FEA) modeling capabilities to analyse magnetic components and assemblies; and we can using Maxwell's magnetic equation design for computer simulation to assist magnet users in calculating magnetic force and selecting the right magnets.

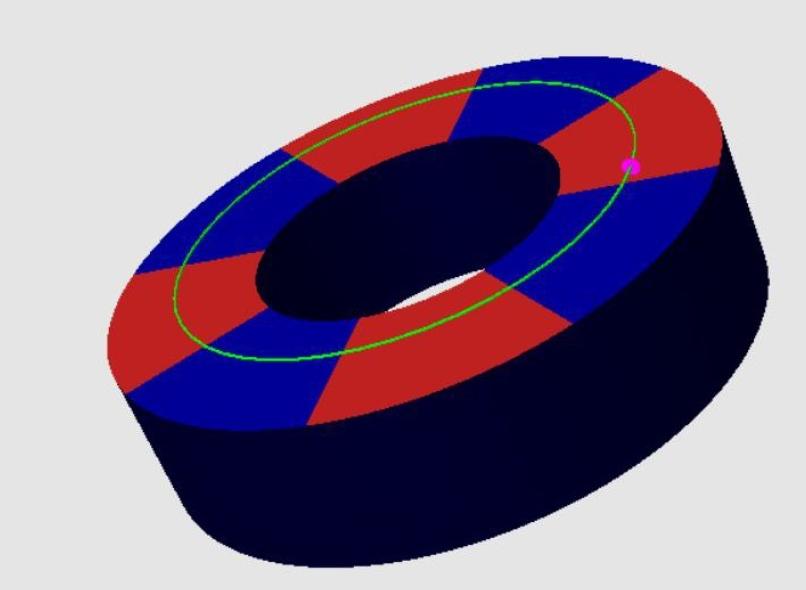

Magnetic component track product applications

Sensor Magnet

Linear Motor Magnet

Large Halbach Array