.png)

.png)

.png)

.png)

.png)

.png)

.png)

Products used in sensor products in instrument and meter. In these areas, the accuracy is very important. so does the magnetic deflection angle. The lower magnetic deflection angle is, the better performance will be, but how to control the deflection angle? Through pressing, sintering and machining process, the magnetization angle is very difficult to control. ±5° is the normal standards of deflection angle. But the magnets used in sensor products requires less than ±3°, thus the pass rate of magnets can only around 70%-80%. All magnets should be done 100% final inspection after magnetization, it is a huge waste of the material and labor.

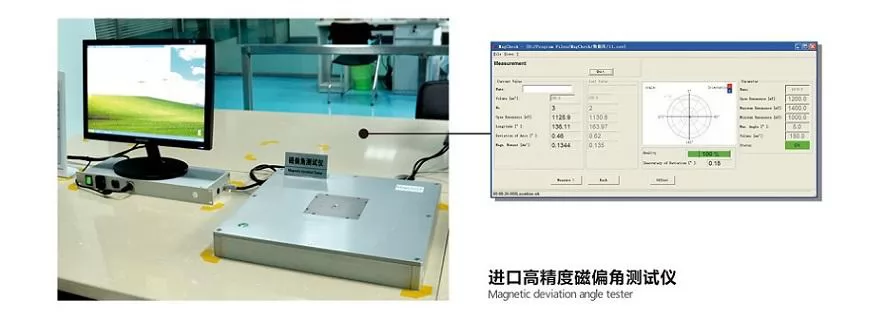

Generally speaking, Sensors have higher standard for magnetic angle deviation. Our professional team, advanced equipment and well-trained QC staff, makes TC the leading company whohas very high qualified rate of low deviation angle product. (it depends on dimensions and requirements).

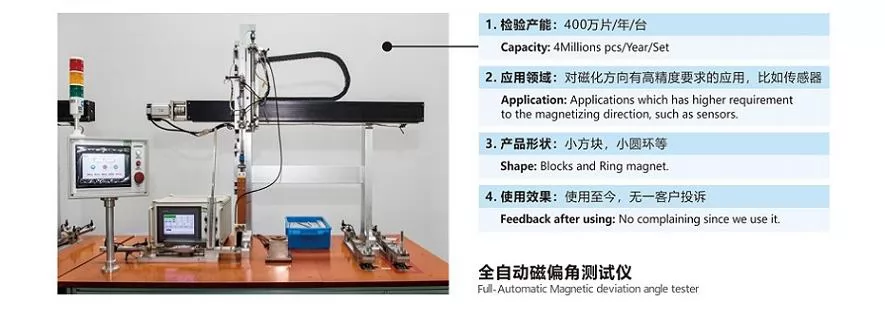

In order to conquer this problem, TC organized a special technical team to do the research, and we found the process pressing and machining are the key points, we are now rising the pass rate to 85%. Low deviation angle product was mostly used in sensor application withhigh requirement and huge quantity. In order to meet the requirement from clients, TC work together with test equipment company to research and develop full-automatic deviation angle tester, which we bought and used to inspect magnetin past years, it ensure our shipping product 100% qualified.

Notes: The deflection angle was related to the shape and dimensions of magnet. Normally, the smaller size of magnet, the harder to control the deflection angle. We have to discuss and confirm the deflection angle when we talk about an exact magnet.

Welcome to contact our professional engineer if you have any question.