.png)

.png)

.png)

.png)

.png)

.png)

.png)

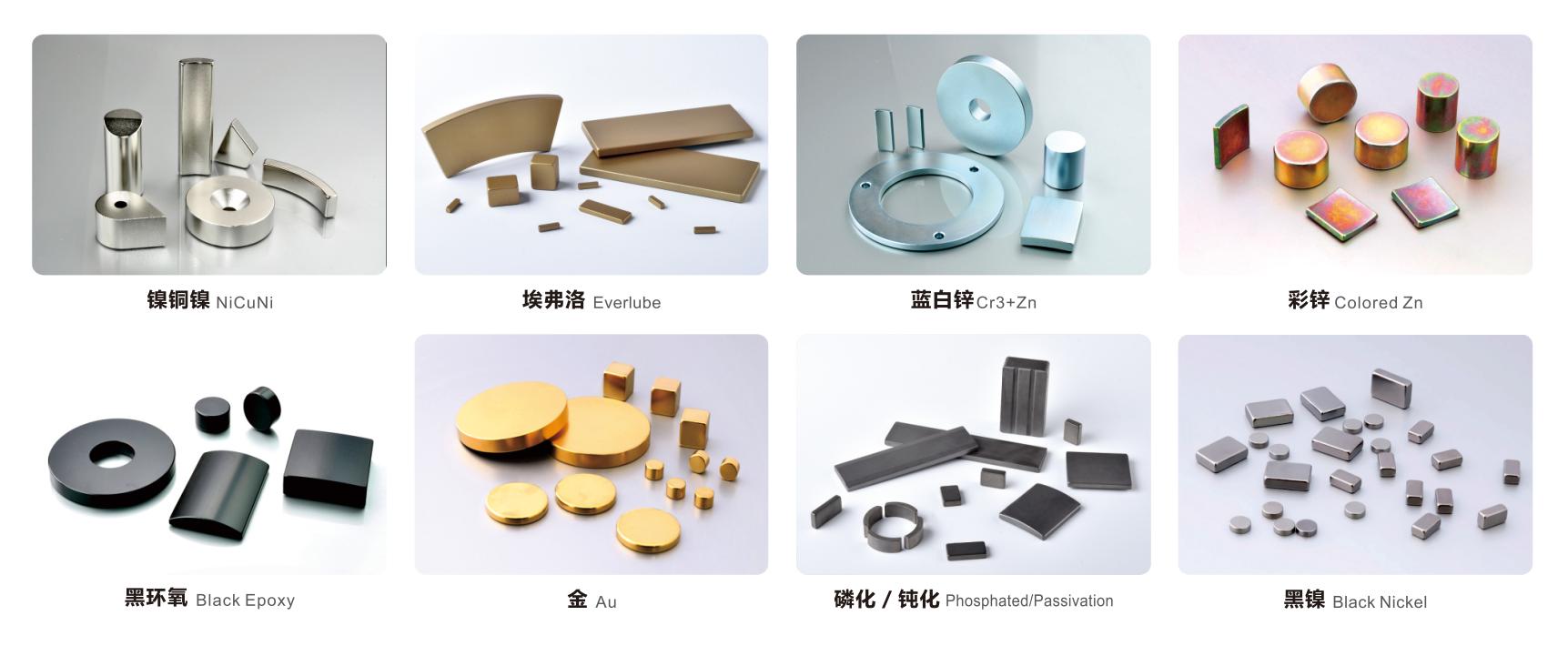

Due to the low corrosion resistance of NdFeB magnets, we need to do surface treatment before applications.

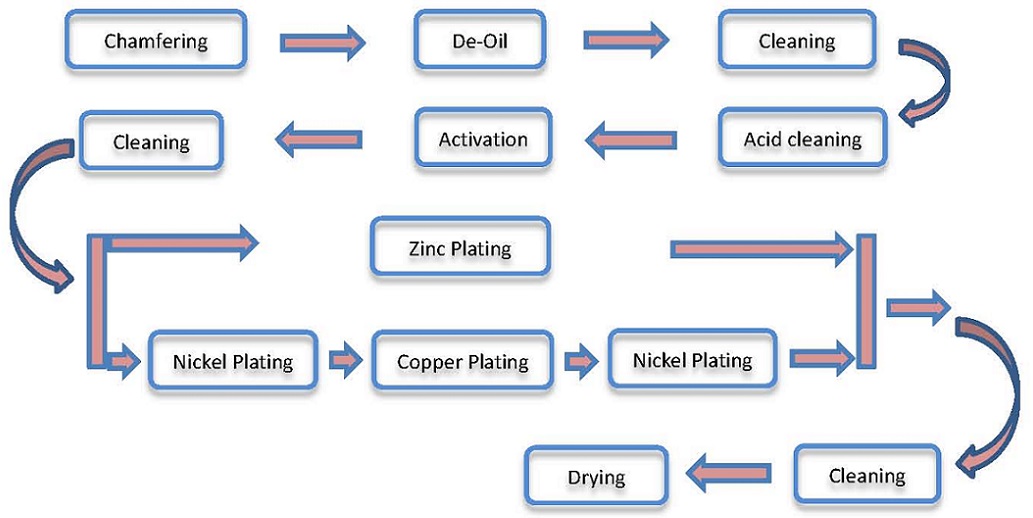

It may take a complete flow and a long time to do chamfering and cleaning, so electroplating needs a period to proceed.

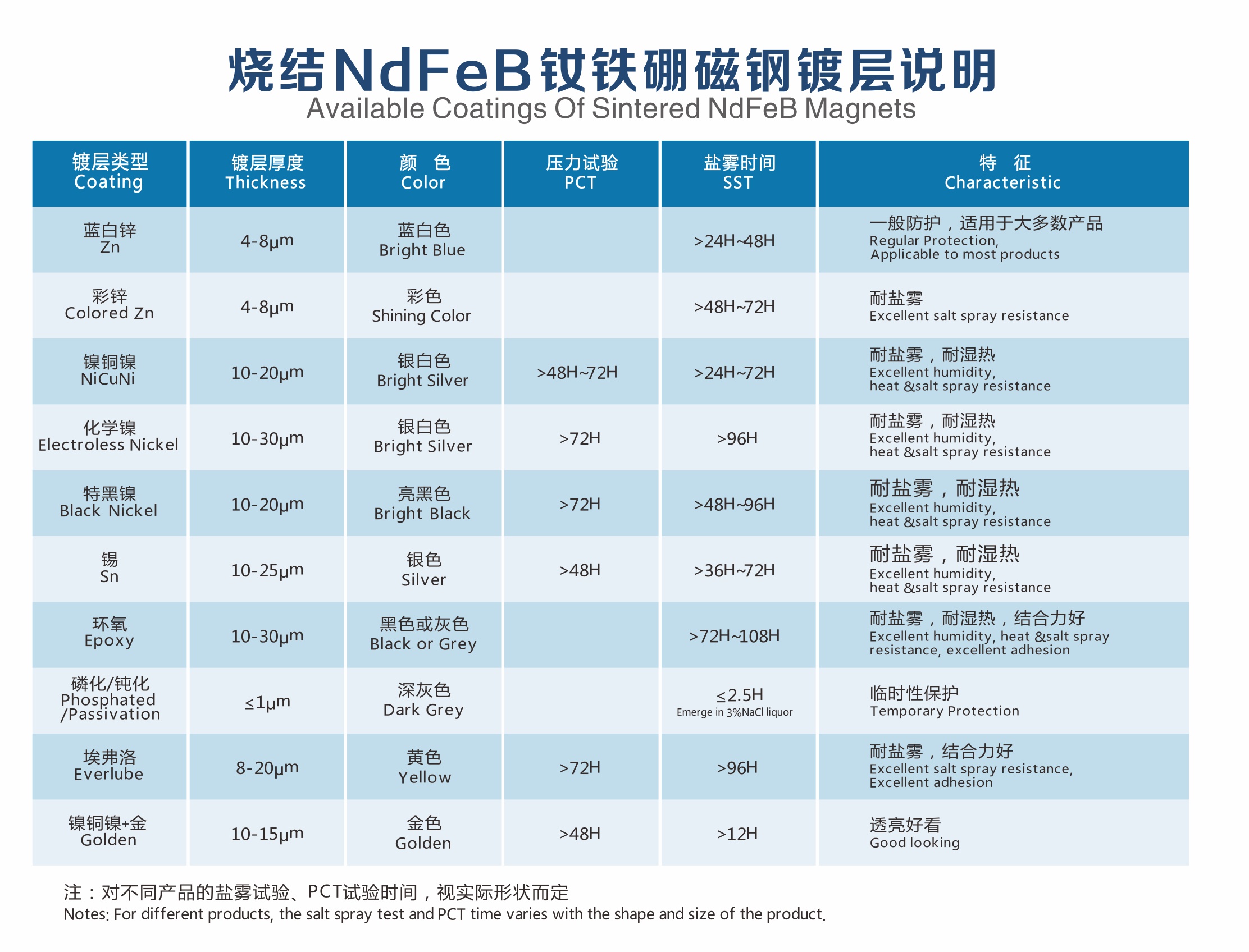

The most popular coatings are Zinc plating, Nickel plating, Epoxy and Passivation, the other coatings are Tin plating, Chromium plating, Gold plating, and Ag plating etc.

Neodymium magnets have a wide range of applications and uses in various fields.

In the field of electronics, neodymium magnets are commonly used in speakers, headphones, and microphones. Their strong magnetic field helps to improve the sound quality and performance of these audio devices.

In the automotive industry, neodymium magnets are employed in electric vehicle motors and hybrid vehicle systems. They contribute to the efficient operation and high power output of these vehicles, enhancing their performance and energy efficiency.

Neodymium magnets are also essential in the manufacturing of hard disk drives (HDDs) and other data storage devices. They help in the precise movement and control of the read/write heads, enabling the storage and retrieval of data.

In the renewable energy sector, they are used in wind turbines to generate electricity. The strong magnetic properties of neodymium magnets aid in the efficient conversion of mechanical energy to electrical energy.

Furthermore, neodymium magnets are utilized in various consumer products such as toys, magnetic jewelry, and refrigerator magnets. They are also employed in industrial machinery and equipment for holding, lifting, and separating magnetic materials.

In summary, neodymium magnets play a crucial role in many aspects of our daily lives and industries, contributing to technological advancements and improved performance in a wide range of applications.

Magnet overview:

Known as "magnetic king", Sintered NdFeB is the third generation rare earth permanent magnet material and the strongest permanent magnet material in the world with excellent magnetic properties. It was widely used in automotive industry, industrial motors, consumer electronics, clean energy, aerospace and other fields; the main component of the magnet is Nd2Fe14B, which has extremely high magnetic properties. Its BH max is more than 10 times higher than that of Ferrite, and the maximum working temperature can reach 250 ℃. Its mechanical properties are also quite good. It is suitable for grinding, wire cutting and drilling and other different processing methods; Due to its poor corrosion resistance, the surface must be coated with different coating processing (e.g. coating with Zn, Ni, Au, Epoxy, etc.) according to different requirements.

Key features:

NdFeB magnet is prepared by powder metallurgy method and its chemical composition is Nd2Fe14B, which has excellent magnetic properties. Its advantages: High demagnetization resistance and high cost performance, while its disadvantages: Relatively strong temperature dependence and relatively weak corrosion resistance, but after suitable grade choosing with cost-effective magnetic circuit design plus correct coating or electroplating of different degrees of coercivity in different use environments, NdFeB can be able to meet different application requirements.

Process Flow:

Alloy Melting Hydrogen Decrepitation Jet Milling Pressing Sintering&Annealing BH-curve test Machining Grain Boundary Diffusion Coating Inspection Magnetizing Packing

Magnetic Performance:

N series: N35-N55, M series:35M-54M, H series:35H-54H, SH series:33SH-54SH, UH series:28UH-52UH, EH series:28EH-50EH, AH series:28AH-48AH

Applications:

Applications: Electric vehicles/automotive industry, Wind turbines, Home appliances, Industrial automation, Electronic products and Medical devices.

Customized NdFeB magnets have the following specific advantages, making them a popular choice in various application industries. The advantages are as follows:

1. High magnetic strength: NdFeB magnets have the highest magnetic strength (magnetic density) among all known permanent magnets, known as the "magnetic king".

2. Compact size: NdFeB magnets have the highest energy density, which means they have a special advantage of "miniaturization" or "lightweighting" in applications where size or weight needs to be minimized, such as in the 3C field.

3. Wide range temperature stability: NdFeB magnets have excellent temperature stability, with a high Curie temperature (complete demagnetization temperature, 310-380 ℃), and can reliably operate within a wide range of working temperatures (working temperature range: -40 ℃ -250 ℃).

4. Multifunctionality: Neodymium iron boron magnets can be customized to suit specific applications. They can be manufactured in various shapes, sizes, and grades to meet specific magnetic requirements.

5. Cost effectiveness: Neodymium iron boron magnets have a high magnetic field strength to cost ratio, making them an economically efficient choice for many applications.

6. Anti-demagnetization: NdFeB magnets have high anti demagnetization, which means they will maintain their magnetism over time even under challenging operating conditions. This makes them suitable for long-term applications that require stable magnetism.

7. Wide application range: NdFeB magnets are used in a wide range of applications, including electric motors, generators, magnetic separators, magnetic resonance imaging (MRI) machines, speakers, magnetic elevators, wind turbines, etc. Its high magnetic strength and versatility make it suitable for numerous industrial, commercial, and consumer applications.

Overall, the advantages of customized NdFeB magnets are their high magnetic strength, compact size, temperature stability, multifunctionality, cost-effectiveness, anti-demagnetization, and wide range of applications. These characteristics make them valuable and increasingly popular magnet materials in various industries.